The International Energy Agency (IEA) has revealed that global investment in solar, wind, batteries, electrolysers and heat pumps rose to US$200 billion (£160 billion) in 2023.

This accounts for a 70% rise in global investment levels in 2022 and is around 4% of global GDP.

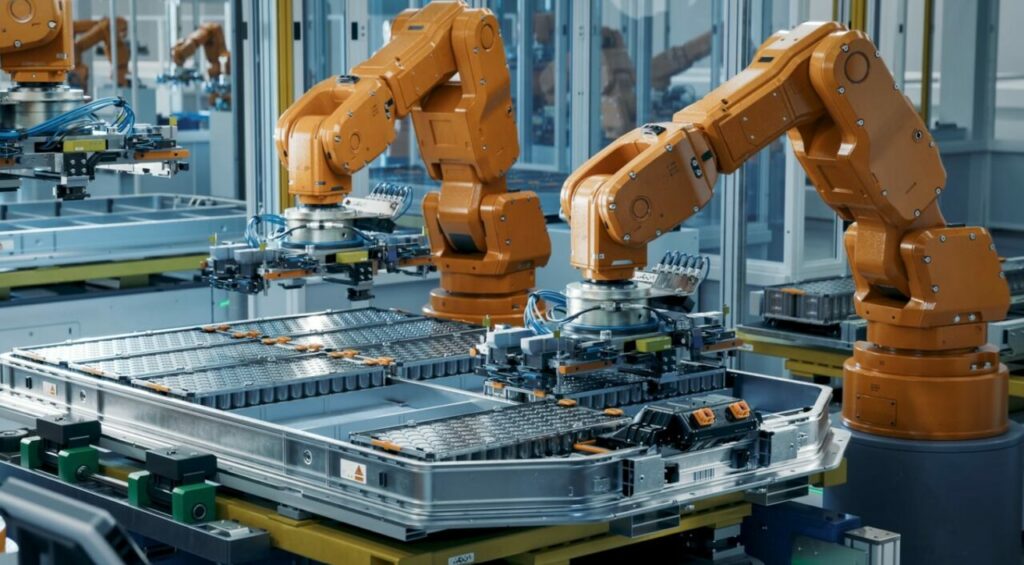

Dubbed Advancing Clean Technology Manufacturing, the report details that solar PV and battery manufacturing led global investment in clean energy, accounting for more than 90% of the total in both years.

Investment in solar PV manufacturing more than doubled to around US$80 billion in 2023, while investment in battery manufacturing grew by around 60% to $110 billion. You can find out more via our sister publication PV-Tech’s coverage here.

Battery storage has increasingly become an important aspect of the renewable sector, granting grid stability and enabling the capture of variable generation technologies like solar and wind.

According to the report, a number of projects in the pipeline will be operational shortly. Almost 40% of investments in clean energy manufacturing expected in 2023 were directed towards facilities due to be operational in 2024. In the case of batteries, this figure increases to 70%.

Committed projects, those under construction or to have reached final investment decisions, through 2025 alongside existing capacity, would exceed by 50% global solar PV deployment needs in 2030 based on the IEA’s Net Zero Emissions by 2050 (NZE) Scenario and meet 55% of battery cell requirements.

Battery manufacturing achieves record year in 2023

Battery manufacturing for use in energy storage and electric vehicles (EVs) saw production total more than 800GWh, rising by 45% from 2022. Capacity additions also surged, with almost 780GWh of cell manufacturing added, around 25% more than in 2022. This raised the total installed capacity to around 2.5TWh, almost three times current demand.

According to the IEA report, if all the announced plans are executed, global battery manufacturing capacity could reach over 9TWh by the year 2030.

The deployment needs for battery manufacturing in 2030 under the NZE Scenario also seem attainable, as more than 90% of the requirements could be met by the expansions that have already been announced and received final investment decisions.

Electrolyser and wind manufacturing see slower growth

Both wind and electrolyser manufacturing grew faster in 2023, although the gains were not as notable as battery and solar PV.

For wind, existing capacity could deliver nearly 50% of the NZE Scenario’s needs in 2030, while announced projects could meet a further 12%. On the other hand, heat pumps saw growth stagnate in various leading global markets, with existing capacity only able to deliver a third of the 2030 needs in the NZE Scenario.

Despite this slow rise in manufacturing, this could grow significantly, given how quickly new plants can be developed alongside capacity expansions.

The geographic concentration of manufacturing these technologies is also not expected to change by 2030, with the majority to be developed in Europe, China and the US. Outside of the main producer countries, Central and South America account for a small share of global production of main wind turbine components, primarily 4% – 6% for nacelles, blades and towers.

Concerningly, virtually no clean technology manufacturing takes place in Africa today. The concentration is more pronounced for upstream solar PV and battery components, but, in a twist, the IEA believes that the prospect of surplus capacity may open up possibilities for greater diversification of production in this area.

Commenting on the report’s findings, IEA executive director Fatih Birol said: “Record output from solar PV and battery plants is propelling clean energy transitions – and the strong investment pipeline in new facilities and factory expansions is set to add further momentum in the years ahead.

“While greater investment is still needed for some technologies – and clean energy manufacturing could be spread more widely around the globe – the direction of travel is clear. Policymakers have a huge opportunity to design industrial strategies with clean energy transitions at their core.”