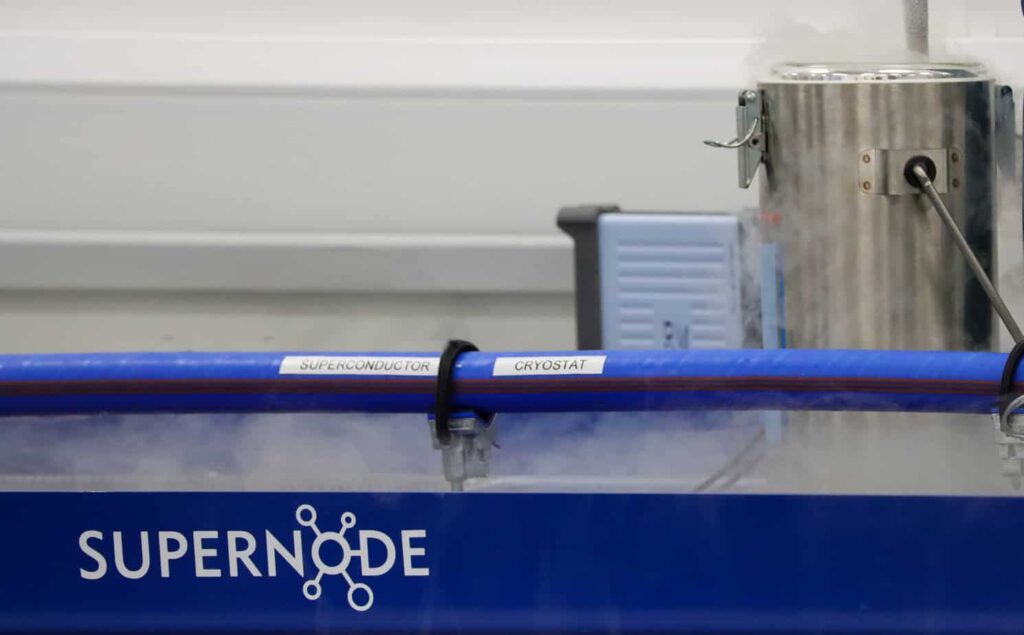

Cable manufacturer SuperNode has announced it will partner with National Grid Electricity Transmission (NGET) on a new project to develop industry standards for high-temperature superconducting (HTS) cabling systems.

The project, titled “Assessment of Superconducting Technologies for Standards Development”, is part of the Strategic Innovation Fund (SIF) Alpha Round 3 competition, funded by Innovate UK and energy industry regulator Ofgem. The project aims to solve the technical challenges involved in deploying HTS systems by identifying what industry standards currently exist for HTS cables – direct current (DC) and overhead lines (OHL) – and developing a plan to create standard specifications where more are needed.

NGET and SuperNode are working with several other partners on this project. These include the University of Strathclyde, which will contribute research on power system analysis and thermal modelling; the University of Manchester, which will lead the review of current HTS industry standards; VEIR, an alternating current HTS specialist who will focus on the requirements for OHL systems; and Frazer-Nash Consultancy, which will manage the alpha phase of the project.

SuperNode CEO John Fitzgerald said: “This project marks an important step for the advancement of superconducting technologies, which hold the potential to revolutionise power transfer and grid capacity expansion. One of the biggest challenges for introducing new technologies into highly regulated industries is the need for clear technical standards, and this initiative aims to bridge that gap”.

Sean Coleman, Strategic Innovation Fund manager at NGET, added: “Innovating and collaborating through initiatives like this can help us make strides towards our decarbonisation goals and delivering the UK’s ambition for a net zero energy system.”

HTS cables could revolutionise transmission

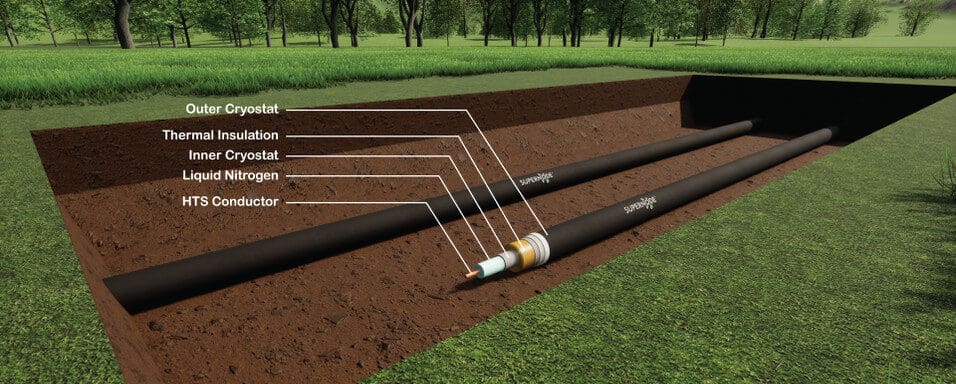

HTS cables are a relatively new entry to the transmission and distribution sector, but could have a revolutionary impact on electricity transmission if their deployment increases. The technology works by placing wires made of a superconductive material, commonly a niobium-titanium alloy, cooled to an extremely low temperature, into a thin pipe that forms a vacuum around the wire and keeps it at this extremely low temperature.

This takes the material below its transition temperature and allows it to transmit current with almost zero electrical resistance. There are several advantages to this; the first and most obvious is the energy saving of near-lossless transmission. Conventional long-distance transmission systems usually experience around a 10% power loss; according to electricity infrastructure firm Nexans, this adds up to around 180TWh of lost power annually across Europe alone.

As HTS cables do not emit heat, unlike traditional transmission systems, they can be directly buried into the ground without the need to install surrounding tunnels and pipes for them, and they do not dry out soil they are buried into. Additionally, HTS cables require much less land for installation, as they can carry five times the current of a conventional cable of the same size, which can be a major cost saver in cities and dense urban areas where land and development costs can be significant.

There are currently very few HTS transmission line projects operating around the world; one of the earliest examples of these being a 0.6km line in Holbrook, Long Island, US, running at 138kV with a 574MW transmission capacity. With this project, SuperNode hopes to bring the technology to the UK electricity network.